Fashionable Algae

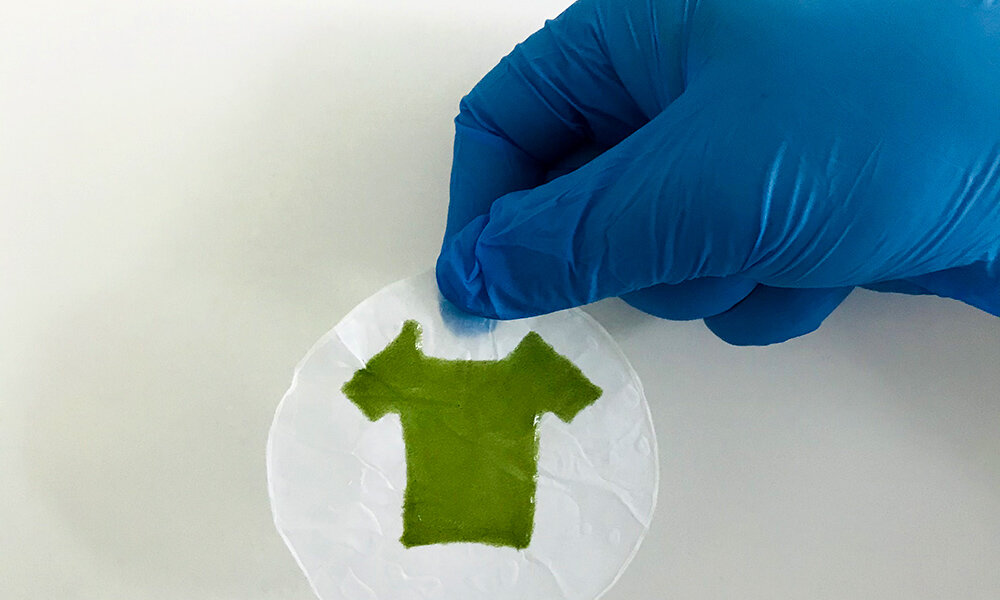

Photo courtesy of University of Rochester.

With new green innovations and technological advances being made most every day in the fashion industry, it’s impossible to know what materials and creation practices might become the norm within the next decade.

But thanks to researchers at the University of Rochester, we might get a fuller picture of what the “fabrics of the future” could be sooner than you think—and it comes in the form bacteria.

As recently reported, for the very first time, researchers at the University of Rochester and Delft University of Technology in the Netherlands used 3D printers and a novel bioprinting technique to actually print algae into living, photosynthetic materials.

While the discovery sounds like it benefits a more scientific base, researchers believe that the material has a number of different applications in everywhere from the fashion sector, to even medical and energy spaces.

Anne S. Meyer, an associate professor of biology at the University of Rochester, said that the “three-dimensional printing has shown to be an effective technology for fabricating living materials that have many environmental and other benefits.”

The ability to photosynthesize these materials is considered to be especially promising considering that this is the first example of a product that boasts enough durability to actually be applied to more tangible applications within the real-world—like material, fashion pieces.

While the innovation is impressive, the work to create the photosynthetic materials has been an ongoing project for Meyer and her team—who started by using nonliving bacterial cellulose, which boasts properties of flexibility and robustness.

The material is especially unique due to its versatile characteristics which make it an ideal prospect for a number of different applications, including products such as “artificial leaves, photosynthetic skins, or photosynthetic bio-garments.”

The artificial technology could change fashion, and the future of staple fashion materials, forever.

Producing bio-garments made primarily from a material like algae could serve as a solution for addressing some of the world’s more pressing climate issues—particularly, the distressing environmental effects brought forth by the fashion industry and its polluting tendencies.

The textile industry—or rather, the fashion industry as a whole—is a key proprietor in cultivating unnecessary waste and producing negative effects on the environment, in turn. Textile mills reportedly generate about one-fifth of the world’s industrial water pollution and use an estimate of around 20,000 different chemicals to produce clothes. As a whole, fashion production makes up about 10% of humanity’s carbon emissions.

But a material like algae—and particularly the bio-garments made from it—could combat the negative environmental effects of the fashion industry’s mass production, and act as a completely biodegradable and sustainably produced alternative to mainstream fashion products.

“Our living materials are exciting because they can sustain themselves over periods of weeks and can be multiplied onsite, so that they have the potential to be truly long-lasting and able to be shared all over the globe as easily as sourdough starter,” Meyer said.

For more information on the research and University of Rochester’s work, visit www.rochester.edu.